Info: +39 0125.71.96.23 – info@micromegael.com

experience, technical capability, flexibility

and fronting edge technologies.

This mixture becomes an added value for those Clients who understand they have a reliable and true partner to face the challenges of the global market with. In these latest years, MICRO MEGA has managed to become a leader on the sector of printed circuits assembly. Not only, it has offered a prompt and high quality service to important domestic and foreign brands also for small and medium-size batches.

OUR LATEST INVESTMENTS:

Selective Soldering in inert atmosphere

SMT soldering

Saldatura Vacuum

Vapour Phase

X ray inspection

Automatic Optic Inspection BF-3Di

SuperSwash washing system

In STRAMBINO, 30 KM from TURIN

Micro Mega owns a spacious and bright warehouse

situated a few kilometres from Ivrea

Top-level

instrumentation

and professionalism

<- SELECTIVE WELDING MACHINE

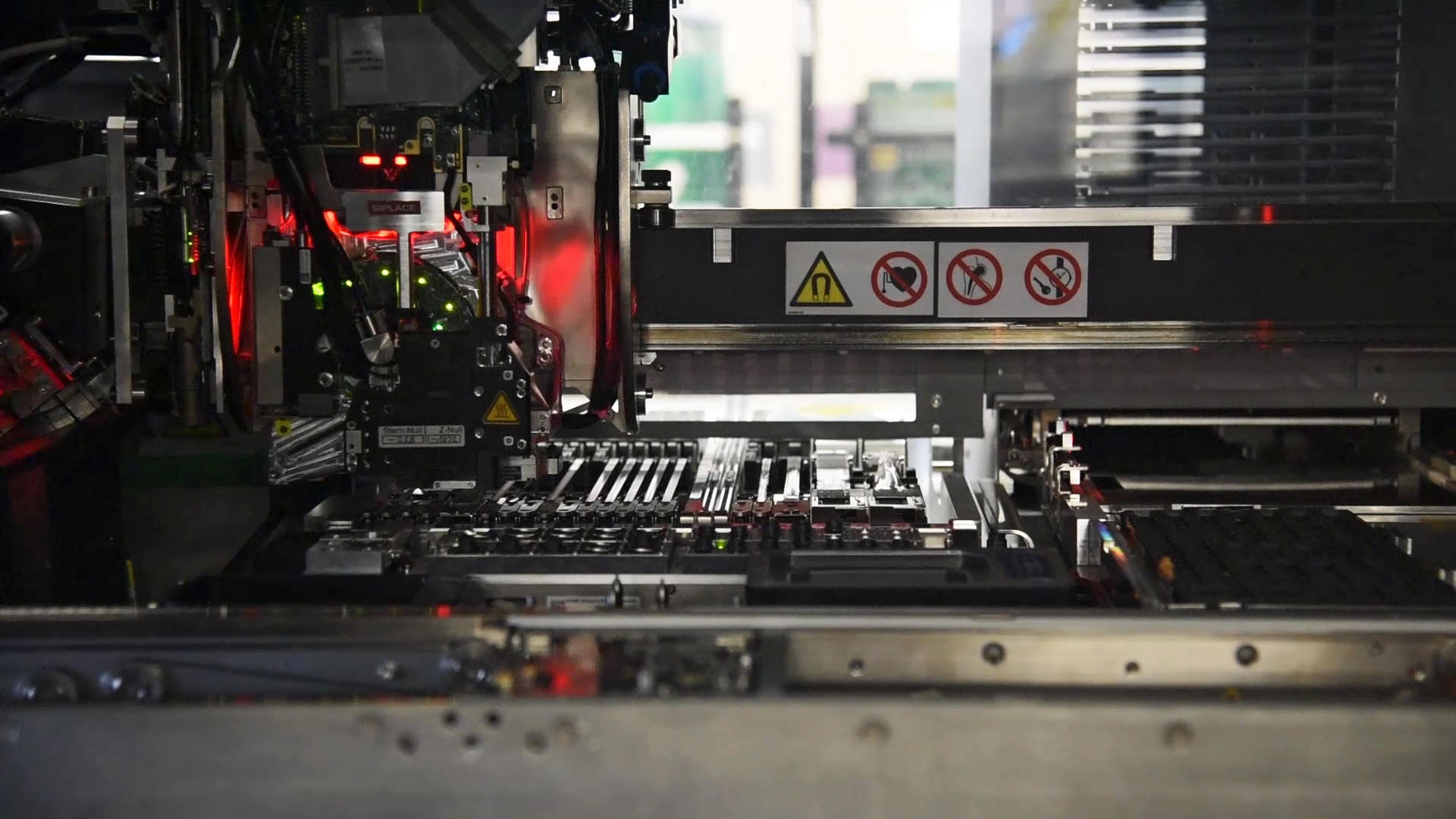

Automatic SMT assembling

lines for SMT boards

ASM SIPLACE ->

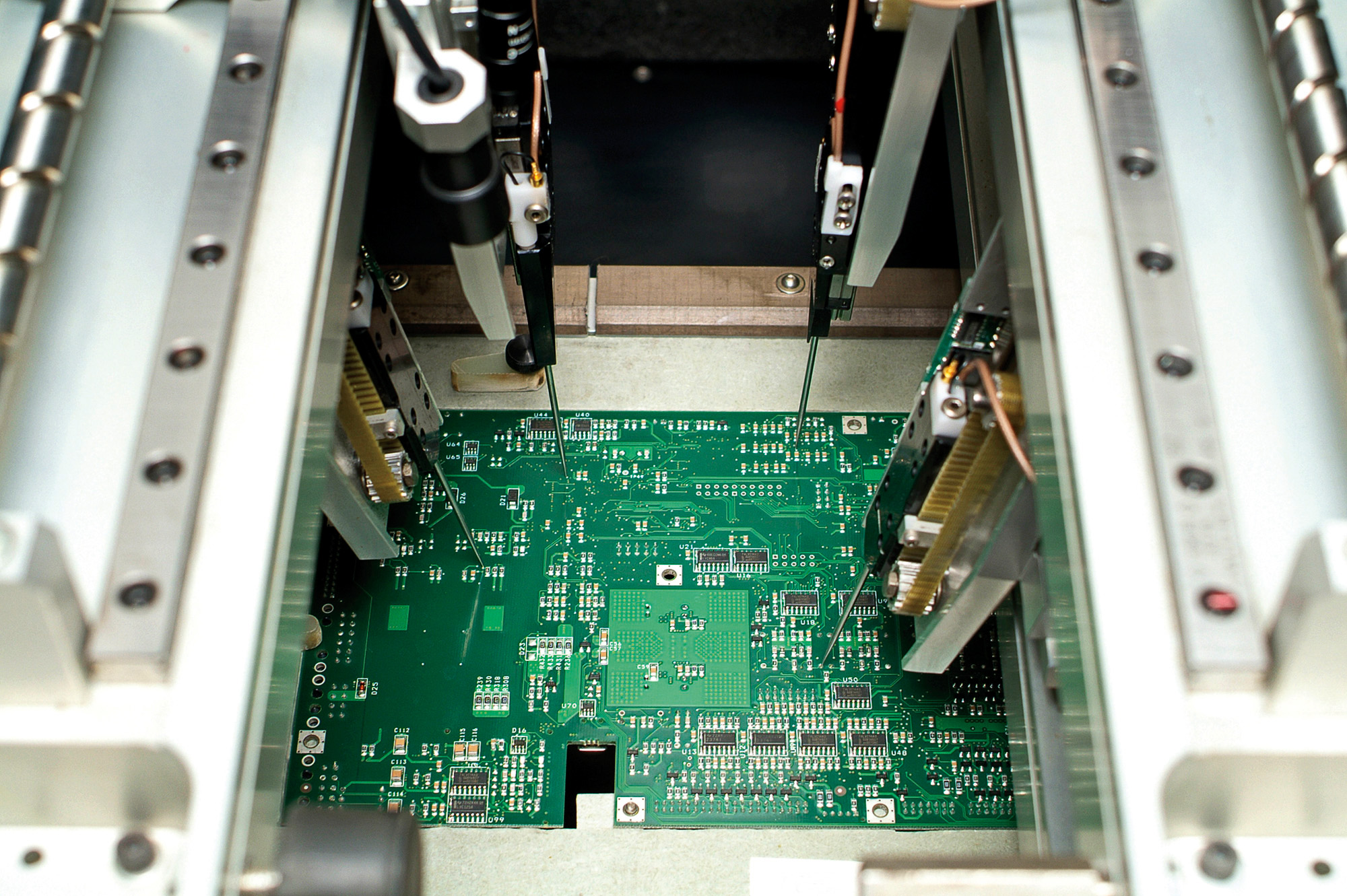

Service of rework

ON BGA BGA, QPP, QFN

<- REWORK BGA STATION

Quality and reliability

they are elements

essential

FLYNG PROBES TEST SYSTEMS ->

PRODUCTS

Assembly lines which, through the automatic processes of screen printing, glue dispensing, assembly, remelting in an inert atmosphere, polymerization, all types of passive and active components are assembled:

GO TO PAGEEQUIPMENT

Assembly lines which, through the automatic processes of screen printing, glue dispensing, assembly, remelting in an inert atmosphere, polymerization, all types of passive and active components are assembled:

GO TO PAGESERVICES

Assembly lines which, through the automatic processes of screen printing, glue dispensing, assembly, remelting in an inert atmosphere, polymerization, all types of passive and active components are assembled:

GO TO PAGE