COMPANY

To be an efficient partner in the world of advanced electronics it is necessary to offer experience, technical capability, flexibility and fronting edge technologies. This mixture becomes an added value for those Clients who understand they have a reliable and true partner to face the challenges of the global market with.

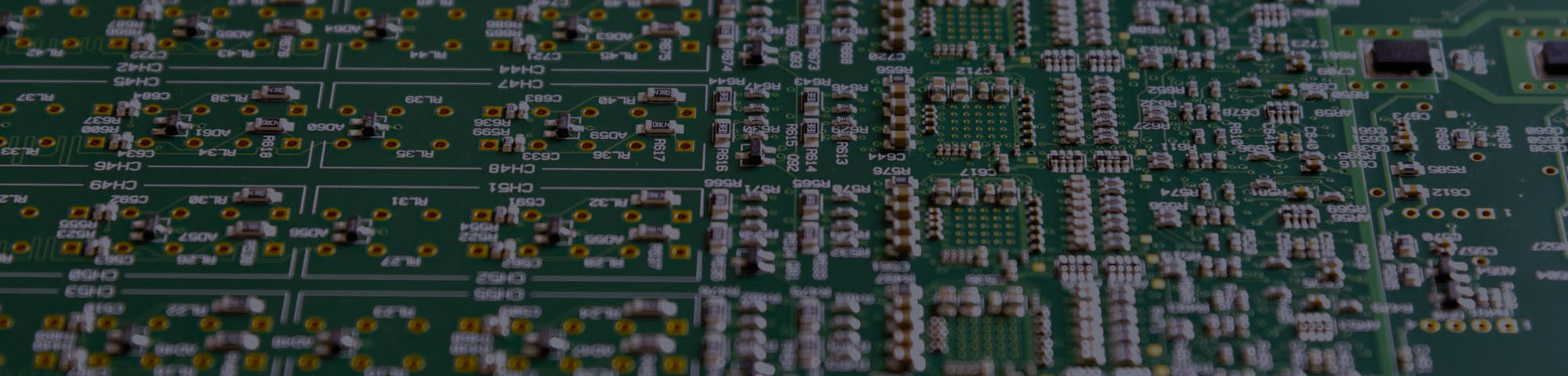

In these latest years,MICRO MEGA MICRO MEGA has managed to become a leader on the sector of printed circuits assembly. Not only, it has offered a prompt and high quality service to important domestic and foreign brands also for small and medium-size batches. Over forty years of experience, a modern and efficient warehouse, a team of skilled and cooperative technicians, attention to quality and punctual deliveries have made MICRO MEGA overcome the crisis and meet new challenges in technology as well as in the services provided.

MICRO MEGA was created with the purpose to satisfy its customers having production needs ranging from small sample batches, one-two pieces, until some thousands of items.

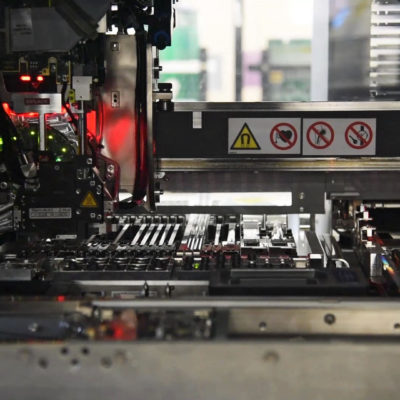

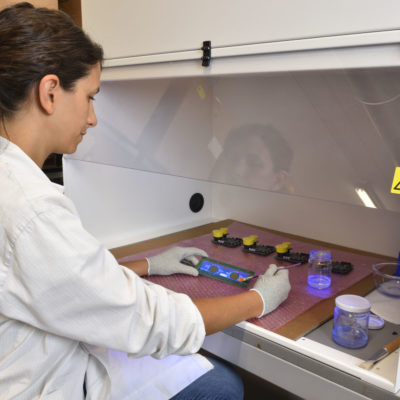

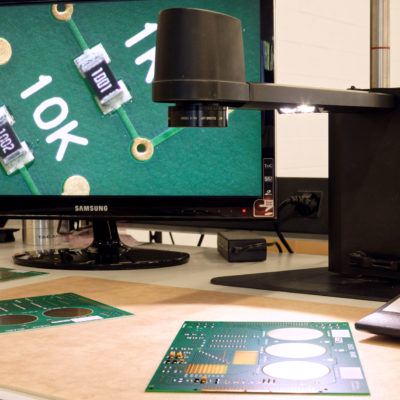

Today, MICRO MEGA experience is specialized in cutting-edge assembly technologies in connection with the types of components and construction peculiarities. In particular, some special personnel has been trained and certified IPC A610 and recently, in addition to the 5 SMD lines, MICRO MEGA machinery has included a line of selective welding that can warranty repetitive actions and the perfect execution of all welding points that, in the past, were carried out manually.

The choice to use latest generation machines has made Micro Mega reach feeder capacity up to 240 tapes of 8mm and 28 waffle Tray as well as components that can be assembled as from dimensions of 01005 mm.

Our customer base covers the broadest sectors:

- military telecommunication

- testing of boards,

- avionics,

- medicine,

- money-cache,

- laser-targeting assists,

- analysis laboratories,

- electronics for vacuum pumps,

- motor racing,

- auto-motive,

- safety of individuals

- GPS positioning.

Customer retention is one of MICRO MEGA’s great strengths. Investments are made to satisfy and anticipate our customers’ new needs:

“the best fuel for our engine”

WHISTLEBLOWING – Segnalazione di reati o irregolarità

Scarica qua la procedura a protezione delle persone che segnalano violazioni a livello aziendale senza ODV.